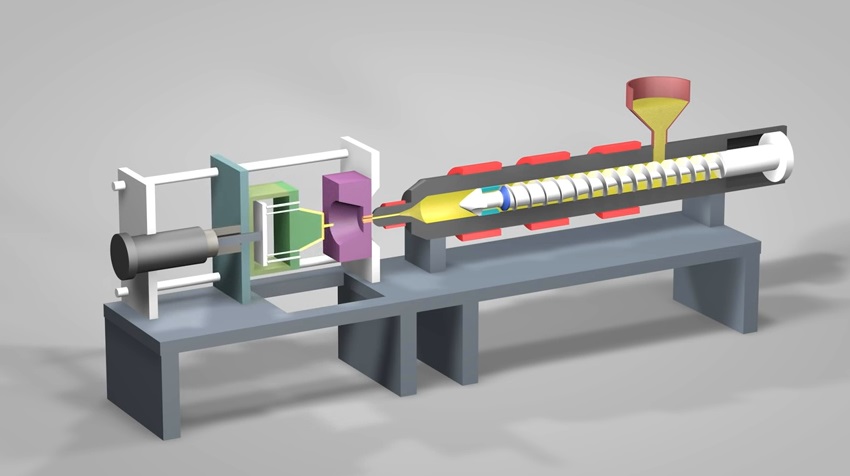

Liquid injection molding (LIM) is a manufacturing technique that combines injection molding and liquid casting to form complex part designs. In LIM, a liquid formulation is injected into a mold under low pressure and heat is applied to cure/solidify the liquid material inside the mold, forming high precision plastic parts. Some key advantages of LIM are its ability to produce intricate designs with tight tolerances, durable finished parts, high production rates and low tooling costs. Parts manufactured via LIM find wide usage in electronics, automotive, medical, aerospace and consumer goods sectors as they help reduce weight and provide corrosion resistance. The global Liquid Injection Molding Market is estimated to be valued at US$ 10.77 Bn in 2023 and is expected to exhibit a CAGR of 4.6% over the forecast period 2023 to 2030, as highlighted in a new report published by Coherent Market Insights.

Market key trends:

One of the major trends in the liquid injection molding market is the rising demand for miniaturization of electronic components. LIM enables the efficient mass production of very small and intricate plastic parts used in microelectronics. This is supporting the growth of MEMS (micro-electro-mechanical systems) and wearable devices industries. Another key trend is the increasing consumption of polyphenylsulfone (PPSU) resin in LIM. PPSU exhibits excellent mechanical and chemical resistance properties making it suitable for medical and healthcare applications. Its adoption is growing in medical devices and implants manufacturing. There is also a shift towards environmentally sustainable LIM formulations with bio-based reagents which offer reduced emissions and improved recyclability. This is propelling research into polymer mixtures incorporating bio-polymers and natural reinforcements.

Porter’s Analysis

Threat of new entrants: The threat of new entrants is low in the liquid injection molding market due to high capital requirements and strong economies of scale possessed by the existing players.

Bargaining power of buyers: The bargaining power of buyers is high in the liquid injection molding market as there are a large number of players providing similar products. Buyers can easily switch between different suppliers based on pricing and quality.

Bargaining power of suppliers: The bargaining power of suppliers is moderate in the liquid injection molding market as switching costs from one supplier to another are low. However, suppliers have negligible threat of backward integration.

Threat of new substitutes: The threat of substitutes is low in the liquid injection molding market as liquid injection molding provides better mechanical properties compared to other molding processes.

Competitive rivalry: The competitive rivalry is high due to many established brands providing competitive pricing and differentiated products.

Key Takeaways

The global Liquid Injection Molding Market Growth is expected to witness high growth during the forecast period of 2023-2030.

Regional analysis:

The North America region dominates the global liquid injection molding market and is expected to grow at a significant rate during the forecast period. This is attributed to the growing demand from the medical segment and the presence of key market players in the region.

Key players:

Key players operating in the liquid injection molding market are Pfizer, Inc., F. Hoffmann-La Roche Ltd, Takeda Pharmaceutical Company Limited, Regeneron Pharmaceuticals Inc., Sanofi, Amgen Inc. The global market is highly competitive owing to the presence of many domestic and international established brands that provide a wide variety of competitive pricing and differentiated liquid injection molding products

*Note:

1. Source: Coherent Market Insights, Public sources, Desk research

2. We have leveraged AI tools to mine information and compile it