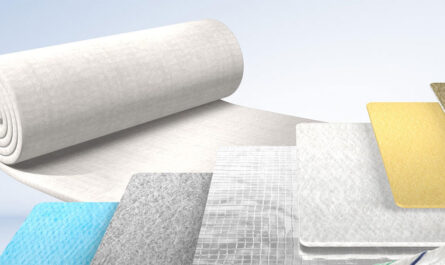

What are Geomembrane?

Geomembrane are synthetic membrane liners that are used in construction for applications such as containment, barriers and covers. They are manufactured from polymers such as high-density polyethylene (HDPE), polyvinyl chloride (PVC), ethylene propylene diene monomer (EPDM) rubber and polypropylene (PP). Geosynthetics are highly impermeable to liquids and gases which makes them suitable for applications requiring protection from contamination.

Manufacturing Methods

The two primary methods used to manufacture geosynthetics are extrusion and calendaring. In extrusion, the raw polymer material in pellet or granular form is heated and forced through a die to form long sheets. Extruded geosynthetics tend to have higher strength. Geomembrane Calendaring involves heating the raw polymer between two heavy rollers to form thin sheets. Calendared geosynthetics are more flexible but have lower puncture and tear resistance compared to extruded ones. Newer methods like welding and seaming technologies allow for large geosynthetic liners to be assembled on-site from smaller factory produced panels. Advances in welding techniques have greatly improved seam performance over the years.

Applications in Waste Containment

Geosynthetics are widely used as lining materials in waste containment facilities such as landfills, surface impoundments and mine tailings ponds. They serve as barriers to prevent contamination of soil and groundwater by leachate from waste residues. HDPE geosynthetics are the most commonly used for these applications due to their high chemical resistance, strength and seamability. Multi-layer composite liners combining a geosynthetic and soil or geosynthetic clay liner provide higher levels of containment. Geosynthetics allow waste sites to comply with strict environmental regulations for impedement of contaminant migration.

Leak Detection in Landfill Liners

Being completely impermeable, even microscopic defects or punctures in Geomembrane geosynthetic liners used at waste sites could potentially lead to contamination issues over time. Thus, maintaining the integrity and performance of these liners is critical. Modern landfill designs incorporate leak detection systems between the primary liner and protective soil/geosynthetic layers. If a leak occurs, liquids will collect in the detection layer and can be promptly identified and addressed before they cause environmental harm. Sensor technologies, pressure mats and automated monitoring systems now make detection highly sensitive and reliable. This, along with development of more durable seam designs, helps ensure utmost protection of the environment by modern engineered landfill containment systems.

Use in Mining Applications

Geosynthetics serve an important purpose in controlling contaminated waters associated with mining activities. They can provide full or partial lining for tailings impoundments to prevent seepage of process chemicals/metals. Geosynthetic clay liners containing bentonite are often used together with HDPE geosynthetics for enhanced performance. For temporary diversions of water or cover applications at mine sites, heavier duty polypropylene geosynthetics have gained preference due to their resistance to weathering and punctures from rough surfaces. Geosynthetic barriers and covers facilitate reclamation of mined land and regulatory compliance regarding stability and control of impacted waters. Research advances continue towards geosynthetics suitable for extremely harsh mining conditions.

Floating Covers on Pretreatment Ponds

Industrial and municipal wastewater treatment plants commonly employ large surface impoundments for purposes such as primary clarification, sludge holding and flow equalization. To prevent odors and emissions as well as control algae growth, geosynthetic covers are often deployed seasonally or permanently over these ponds. Lightweight high density polyethylene (HDPE) or linear low density polyethylene (LLDPE) geosynthetics are favored for cover applications due to their strength, weatherability and welding properties. Floatation devices such as polystyrene panels attached along the edges ensure the geosynthetic cover remains tensioned across the pond surface. This simple yet effective technique helps treatment facilities achieve regulatory compliance while protecting the environment from noxious emissions.

Agricultural & Irrigation Applications

Geosynthetics are now regularly used in agriculture for various purposes such as retaining irrigation water, covering silage and manure storage structures, and providing barriers under feedlots. These applications help improve productivity, reduce waste and protect soil/water resources. Porous geosynthetics have been developed for dust control on unpaved roads on farms. Geosynthetics allow efficient construction of small farm ponds for watering livestock. Research continues towards UV light-stabilized formulations suitable for extended outdoor exposure without degradation. As more farmers adopt sustainability practices, geosynthetics will likely see widening usage for diverse on-farm applications requiring impermeable barriers or covers. This trend benefits agricultural productivity and the environment alike.

Ongoing Advancements

With continuous improvements to polymer formulations, seam designs, installation methods and leak detection systems, the functionality and lifespan of geosynthetics keep increasing. Modern HDPE geosynthetics can last over 50 years with minimal deterioration when properly installed and maintained. New materials like flexible polyolefins show promise for complex site conditions.

Nanotechnologies may further enhance properties like self-healing in the future. Geosynthetics have undoubtedly emerged as a key technology enabling modern landfills, mines and wastewater facilities to achieve high levels of eco-efficiency and protection of water/soil resources. Their versatility across infrastructure, agriculture and other sectors underscores their growing importance in environmental protection applications worldwide.

*Note:

1. Source: Coherent Market Insights, Public sources, Desk research

2. We have leveraged AI tools to mine information and compile it

About Author:

Ravina Pandya, Content Writer, has a strong foothold in the market research industry. She specializes in writing well-researched articles from different industries, including food and beverages, information and technology, healthcare, chemical and materials, etc. (https://www.linkedin.com/in/ravina-pandya-1a3984191)