Ultraviolet (UV) coatings have emerged as a valuable addition to the paints and coatings industry in recent years. These advanced coating technologies provide protective and functional properties beyond traditional coatings. As environmental regulations continue to evolve and consumer demand grows for sustainable products, UV coatings offer advantages that make them well-suited for a range of applications. This article explores some of the key attributes and value propositions of UV coating technologies.

Fast-Curing Properties Enable Efficiency Gains:

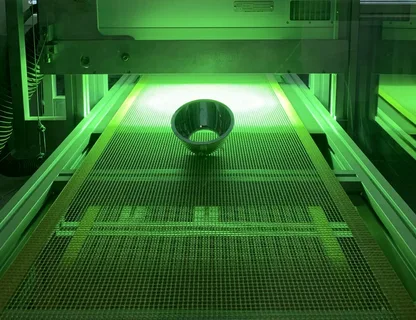

One of the major advantages of UV coatings is their ability to cure almost instantly when exposed to ultraviolet light, as opposed to air-drying coatings that can take hours or days to fully cure. This fast-curing property allows for dramatic improvements in production throughput and turnaround times in various industries. Manufacturers that utilize UV coatings in their assembly and finishing processes are able to move products through more quickly thanks to reduced drying and curing times. The fast cure speeds also enable just-in-time manufacturing approaches where items can be coated and finished right before packaging or shipping without lengthy drying intervals. Across industries like wood flooring, automotive parts, and electronics assembly, UV coatings have unlocked productivity and efficiency gains through their rapid curing profiles.

Environmentally-Friendly Attributes Support Sustainability Goals:

In addition to productivity benefits, UV coatings are highly valued for their environmentally preferable attributes compared to solvent-based alternatives. UV coating technologies are largely water-based or 100% solids, meaning they contain no or minimal volatile organic compounds (VOCs) that can harm air quality and contribute to ground-level ozone formation. The lack of solvent evaporation also means UV coatings have very low VOC emissions during both application and the curing process. This makes them compatible with stringent environmental regulations and brings facilities into compliance with emissions standards. For companies pursuing sustainable product design and manufacturing goals, UV coatings allow them to lower their environmental footprint in a meaningful way. Their “green” credentials are highly valued by forward-thinking organizations and eco-conscious consumers.

Superior Application Versatility Drives Adoption:

Subheadings:

– Automotive Coatings Applications

– Wood Finishing Uses

– Graphics & Packaging Implementations

Automotive Coatings Applications:

Within the automotive industry, UV coatings have found widespread use in applications like clearcoat finishes, automotive refinishing, and coating of plastic interior and exterior car parts. Their fast cure times enable the rapid production of clearcoat finishes without delays compared to traditional baked enamel finishes. For repairs and refinishing, UV-curable coatings allow shops to turn around jobs in hours rather than days. Plastic bumpers, trim pieces, and components can also be efficiently coated and finished on the assembly line using UV technologies. As the vehicles market moves increasingly towards lighter weight plastic and composite materials, the need for fast, durable coatings drives further adoption of UV alternatives.

Wood Finishing Uses:

UV coating technologies have revolutionized wood finishing operations as well. Hardwood flooring manufacturers now predominantly use UV-cured polyurethane and acrylate coatings to produce durable, scratch-resistant flooring at high speeds on automated lines. The rapid cure rates avoid delays in packaging and shipping finished wood floors. For cabinetry, furniture, millwork and other wood product applications, UV coatings have enabled water-based and zero-VOC options providing the performance requirements of the industry. With wooden component construction continuing to gain popularity in green building, opportunities exist for UV coating growth in this market.

Graphics & Packaging Implementations:

Within printing, graphics, and packaging, UV ink and coating technologies represent a mature segment with expanding potential. Flexographic, screen, gravure, and digital UV inkjet printing methods have transformed short-run packaging and labels production with fast turnarounds. UV coatings are widely applied in post-printing processes to protect graphics and provide functional barrier properties for food and healthcare packaging. As e-commerce drives mass customization needs, the versatility and efficiencies of UV technologies are highly valued. Emerging packaging trends towards sustainability additionally support growth of these solvent-free options. Ongoing innovation around LED-curable inks and coatings also promises to unlock new implementation pathways.

Superior Performance and Protection Attributes are Valued:

Subheadings:

– Durability and Scratch Resistance

– Chemical Resistance Qualities

– Barrier Properties Support Food Safety

Durability and Scratch Resistance:

Beyond speed of processing, UV Coatings Value are highly valued for the protection and durability attributes they provide finished products. The crosslinked molecular structures formed during UV curing endow excellent hardness and scratch resistance to coated surfaces. Automotive original equipment manufacturers especially rely on the superior abrasion properties of UV-cured clearcoats to deliver multi-year gloss retention and protection of vehicle exteriors. For high-traffic flooring installations, the durability of UV polyurethane and acrylate coatings is a major selling point offering long-lasting, low-maintenance performance. These highly crosslinked network structures make UV coatings resistant to abrasion, marring and damage during product use cycles.

Chemical Resistance Qualities:

In addition to physical durability, UV coatings impart outstanding chemical resistance allowing protected use in diverse industrial and consumer applications. The chemical structures formed during UV curing result in highly inert barrier properties. Automotive and transportation components require coatings durable against fuels, oils, lubricants, de-icers and other chemical exposures during service. Similarly, electronic device touchscreens and enclosures demand protection from fingerprints, sealants and cleaning agents. Floor finishes need to withstand exposure to common commercial and household chemicals as well. The chemical resistance of UV coating technologies supports product longevity across varied use environments.

Barrier Properties Support Food Safety:

Within food packaging, advanced barrier capabilities of UV coatings are highly valued. Many UV systems are optimized to form defect-free polymeric coatings that inhibit migration of moisture, oxygen, and fats/oils between package interior and exterior. This functionality is critical for protecting perishable and oxygen-sensitive food and beverage products from degradation factors like moisture, oxidation and lipid staining. By extending shelf life through active and passive barrier attributes, UV coatings help enable innovative packaging designs aimed at reducing food waste. For applications dealing with healthcare and personal care products sensitive to contamination, the hygienic protectiveness of UV coatings represents an important quality attribute as well.

*Note:

1.Source: Coherent Market Insights, Public sources, Desk research

2.We have leveraged AI tools to mine information and compile it