Market Overview:

The global 3D Printing Extrusion Materials Market is estimated to be valued at US$3.69 billion in 2023 and is expected to exhibit a CAGR of 19.40% during the forecast period 2023-2030, as per a new report by Coherent Market Insights. This market primarily caters to the rising demand for advanced materials used in 3D printing applications across various industries. These materials, such as polymers, metals, and ceramics, find extensive use in manufacturing prototypes, customized products, and complex parts.

Market Dynamics:

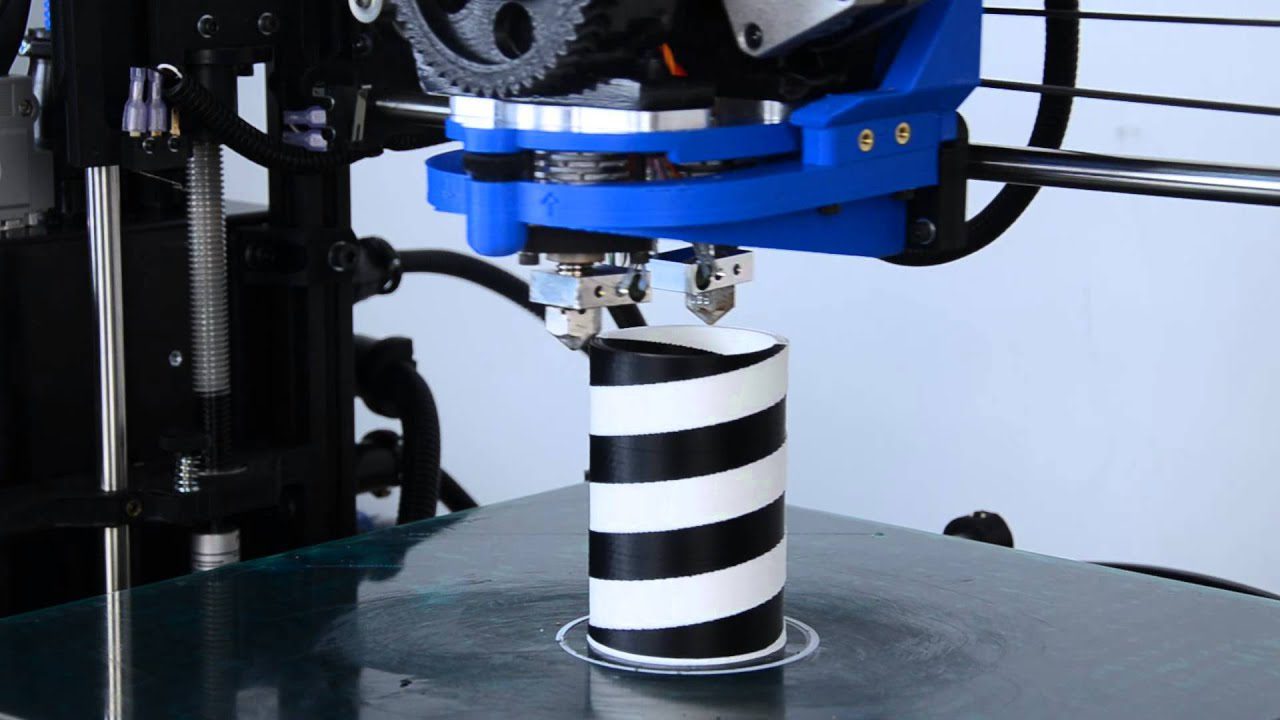

The market dynamics for the 3D Printing Extrusion Materials Market can be attributed to two key drivers. Firstly, the increasing adoption of 3D printing technology across various industries, including automotive, aerospace, healthcare, and consumer goods, is driving the demand for extrusion materials. The ability of 3D printing to reduce production time and costs while enabling complex designs is a significant factor propelling market growth. For example, in the automotive industry, 3D printing is used to print lightweight and customized components for vehicles.

Secondly, advancements in material development and innovation are fueling market growth. The continuous research and development efforts by key players have led to the introduction of new materials with improved mechanical properties and functionalities. Developments such as the introduction of advanced polymers, biocompatible materials, and metal alloys have expanded the applications of 3D printing in various sectors.

Market Key Trends:

One key trend observed in the 3D Printing Extrusion Materials Market is the growing use of sustainable materials. With increasing environmental concerns, there is a rising demand for eco-friendly materials that can be used for 3D printing. Materials such as biopolymers made from renewable sources, recycled plastics, and bio-based resins are gaining popularity. For instance, companies are using bio-based polylactic acid (PLA) materials, which have a lower carbon footprint compared to traditional plastics, for printing applications.

SWOT Analysis:

– Strength: 3D printing extrusion materials offer advantages such as high precision, increased design flexibility, reduced material waste, and cost-effective manufacturing processes.

– Weakness: Limited production volumes and slower printing speeds compared to traditional manufacturing methods can be considered as weaknesses.

– Opportunity: The increasing adoption of 3D printing in the medical and dental sectors presents opportunities for the market growth of extrusion materials. The ability to produce complex, patient-specific medical devices and implants is a significant opportunity.

– Threats: The high cost of 3D printers and materials, as well as the lack of standardization and regulations, pose challenges to the market’s growth potential.

Key Takeaways:

The global 3D Printing Extrusion Materials Market is expected to witness high growth, exhibiting a CAGR of 19.40% over the forecast period. The increasing adoption of 3D printing technology and advancements in material development are driving market growth. Regions such as North America, Europe, and Asia-Pacific are witnessing significant growth due to the presence of key market players and rising investments in research and development.

Key players operating in the global 3D Printing Extrusion Materials Market include 3D Systems Corporation, Stratasys Ltd., Materialise NV, EOS GmbH, Arkema S.A., SABIC, Evonik Industries AG, DuPont de Nemours Inc., BASF SE, Dow Chemical Company, HP Inc., Royal DSM N.V., EnvisionTEC GmbH, CRP Group, Carbon Inc. These companies are constantly focusing on product innovation and strategic collaborations to strengthen their market position and cater to the growing demand for advanced extrusion materials in 3D printing applications.

In conclusion, the 3D Printing Extrusion Materials Market is expected to witness significant growth in the coming years. The ability of 3D printing to revolutionize industries through rapid prototyping, customization, and efficient manufacturing processes is driving the demand for extrusion materials. The adoption of sustainable materials and ongoing advancements in material development will further propel market growth, making it an exciting industry to watch.